How is the underfloor heating water manifold system designed for optimal efficiency?

1.Heat Load Analysis:

Before designing the manifold system, conduct a thorough analysis of the building's heat load requirements. Consider factors such as insulation, building orientation, and local climate to determine the heating needs for each room.

2.Zoning:

Divide the building into zones based on similar heating requirements. Zoning allows for more precise control over individual areas, optimizing energy usage and ensuring that each room receives the appropriate level of heating.

3.Pipe Layout and Spacing:

Plan the layout of the underfloor heating pipes to maximize the heat distribution across the floor surface. Proper spacing and routing of pipes help ensure uniform heating without hot or cold spots.

4.Pipe Sizing:

Calculate the appropriate diameter for the underfloor heating pipes based on the required flow rates and pressure drops. Proper sizing ensures efficient heat transfer and minimizes energy consumption.

5.Balancing the System:

Use balancing valves or flow regulators to achieve a balanced flow of water through each circuit. Balancing helps maintain consistent temperatures across all zones and prevents some areas from overheating while others are underheated.

6.Temperature Control:

Incorporate temperature control devices, such as thermostats and mixing valves, to maintain the desired temperature in each zone. This prevents excessive energy consumption and improves comfort by preventing overheating.

7.Insulation:

Ensure proper insulation of the underfloor heating pipes and the manifold to minimize heat loss. Well-insulated pipes and components contribute to the overall efficiency of the system.

8.Efficient Pump Operation:

Select pumps that are appropriately sized for the system and use variable speed controls to match the flow rate to the actual heating demand. This prevents unnecessary energy consumption during periods of lower heating requirements.

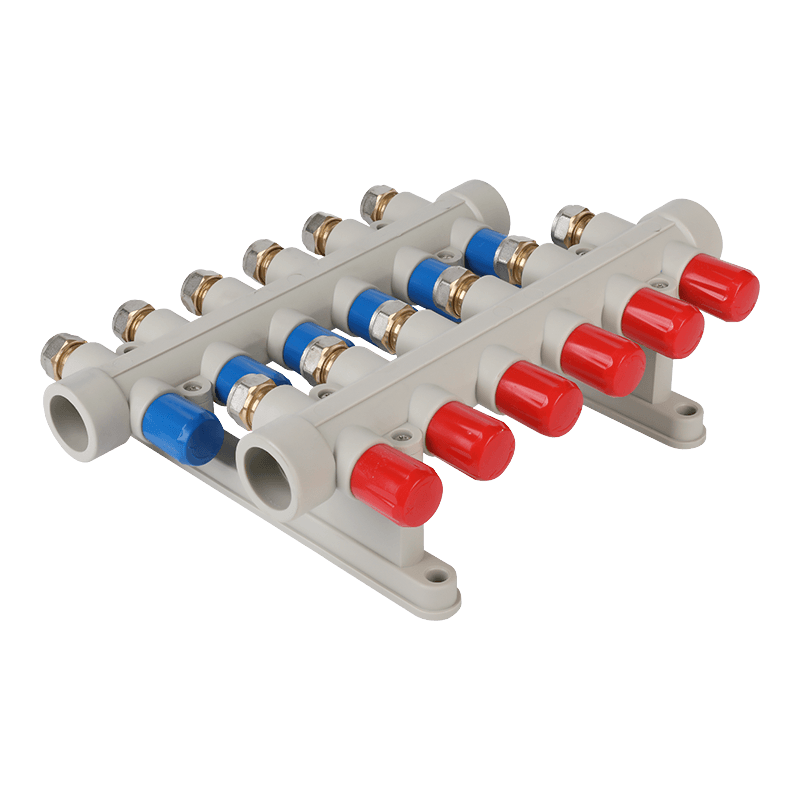

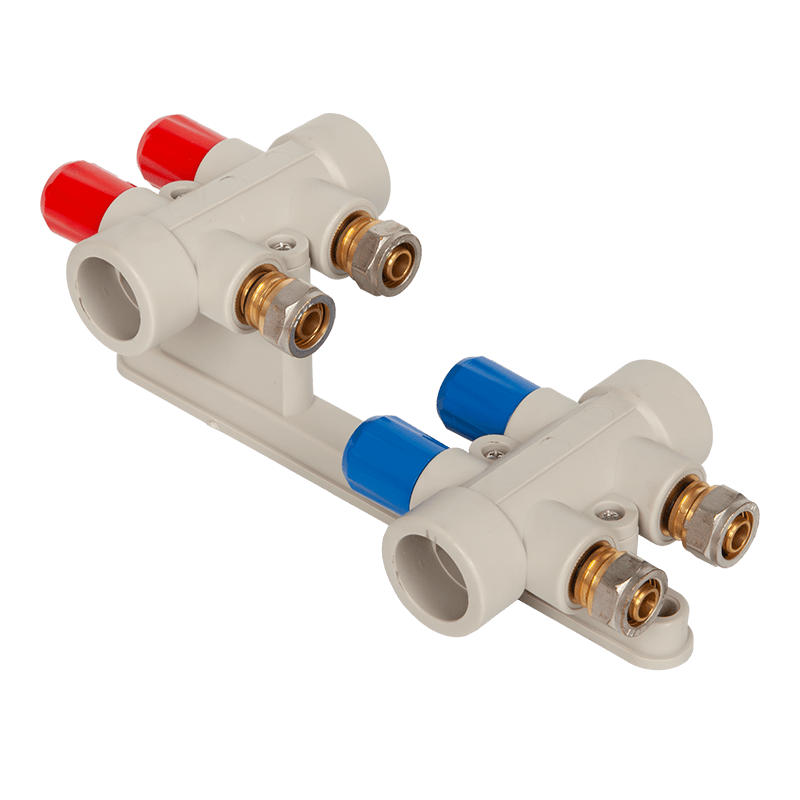

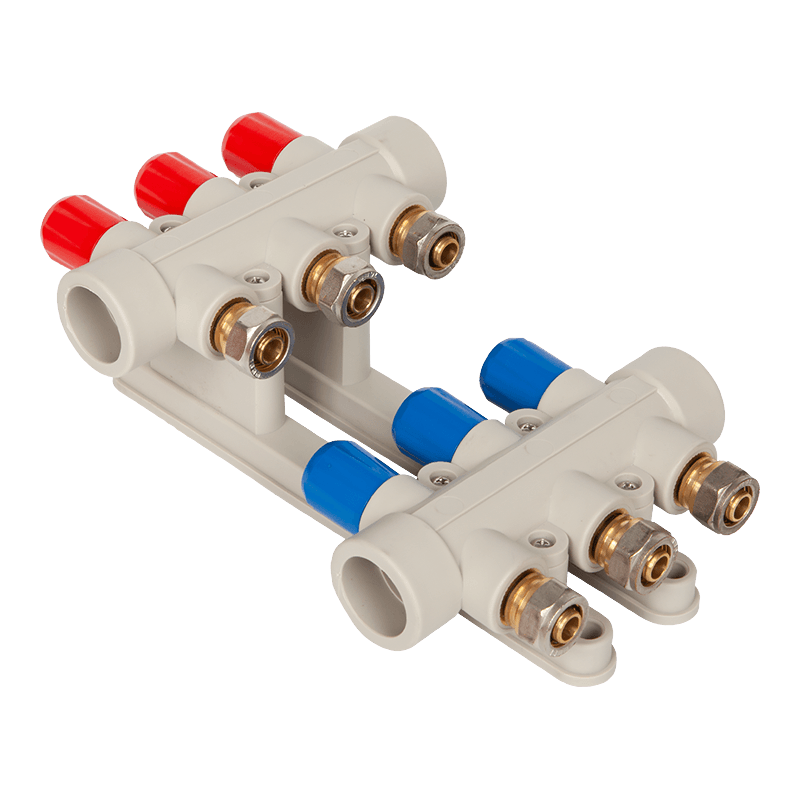

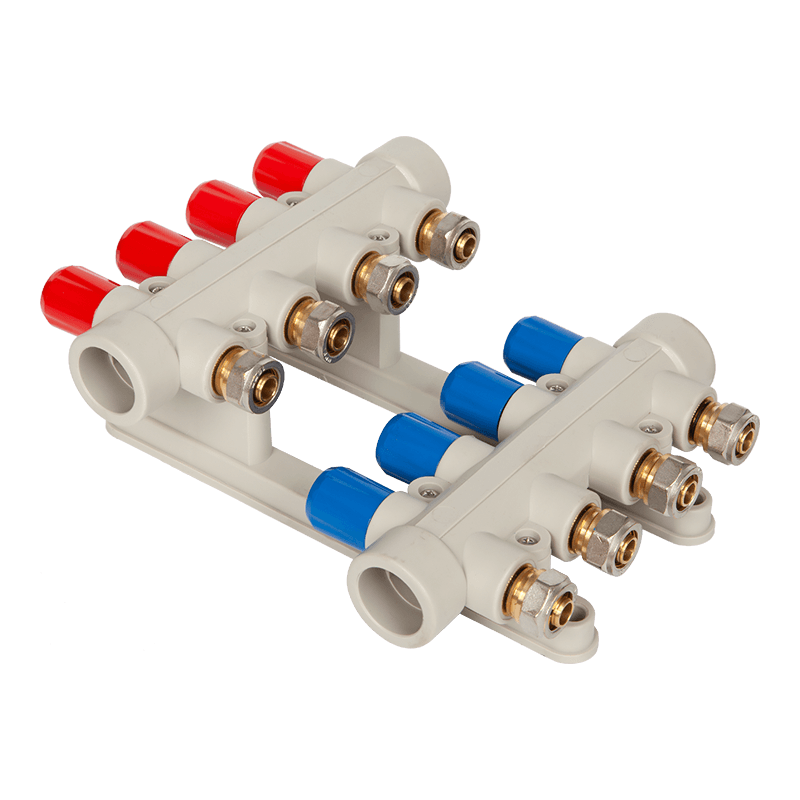

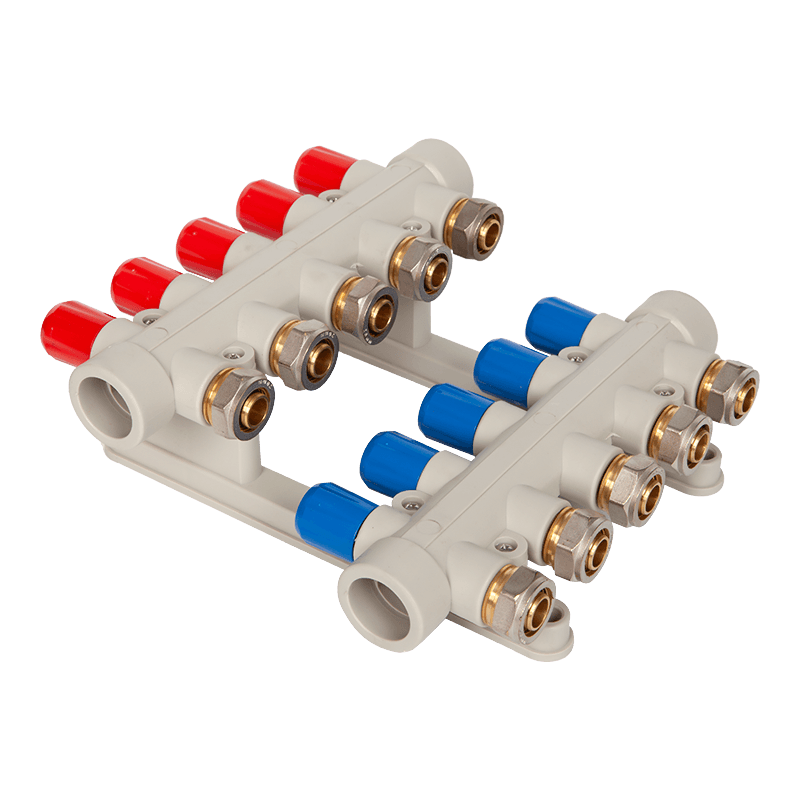

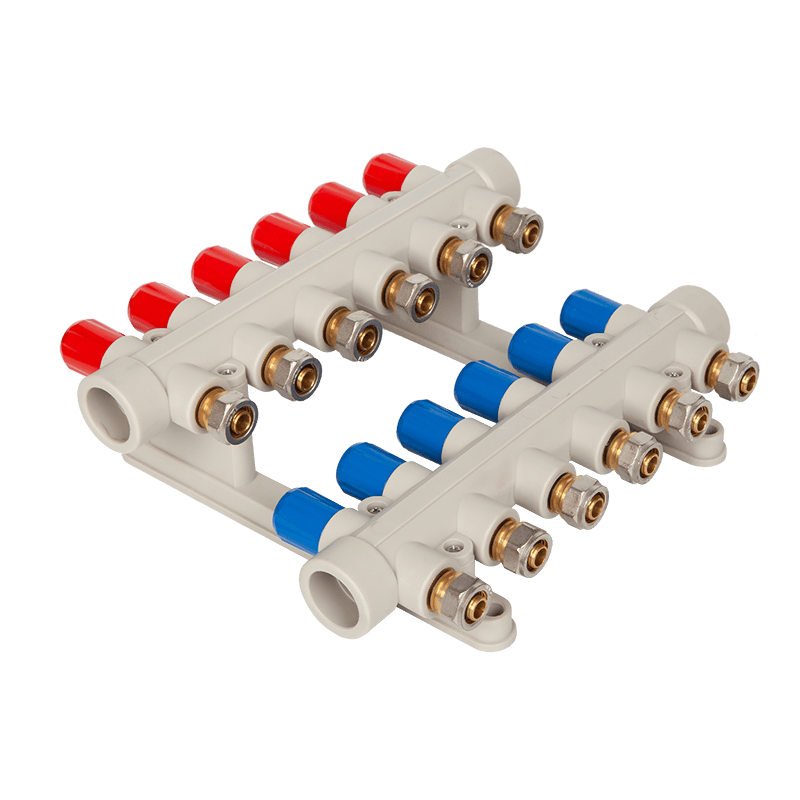

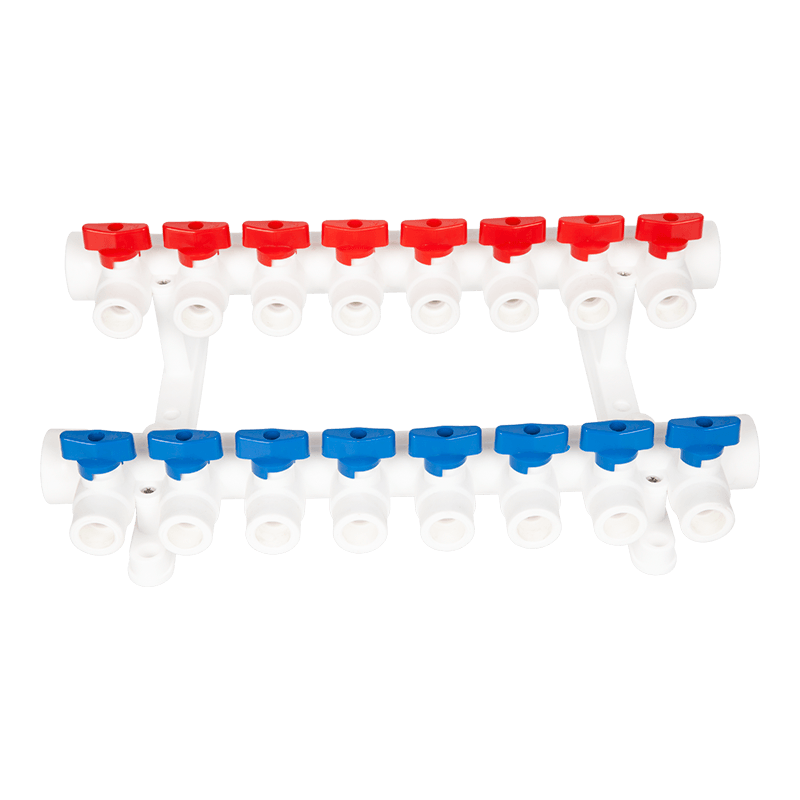

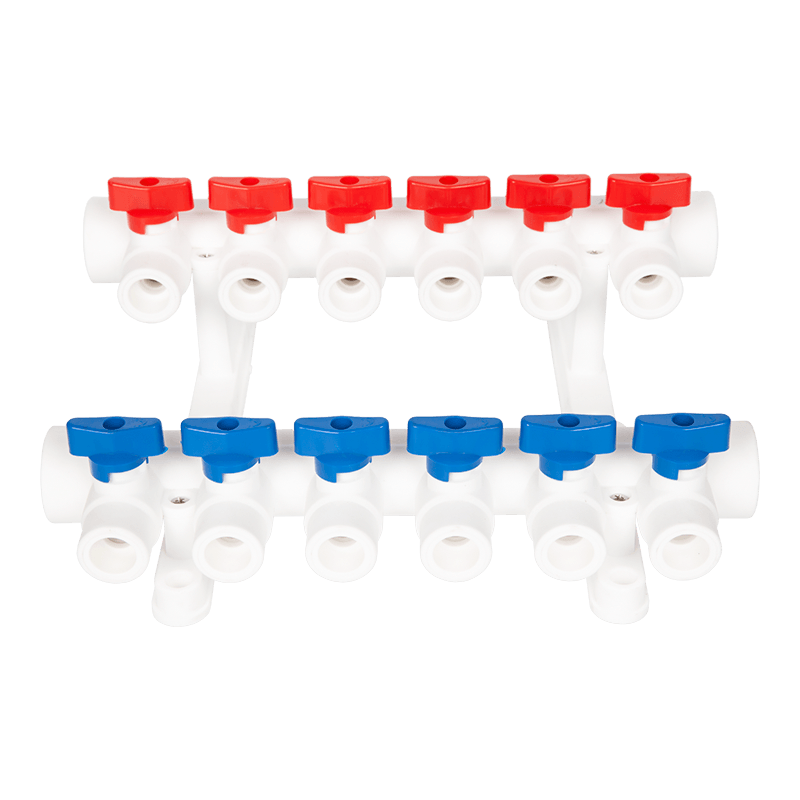

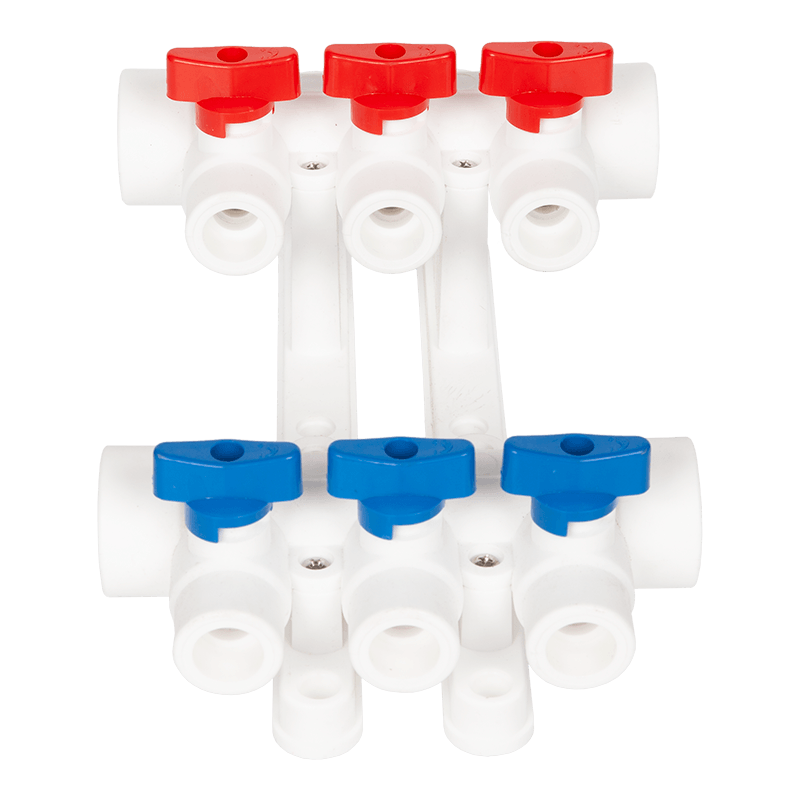

An

underfloor heating water manifold is a central distribution point for the warm water that circulates through the pipes in an underfloor heating system. It helps regulate the flow of heated water to different zones or loops within the floor, ensuring even and efficient heating.

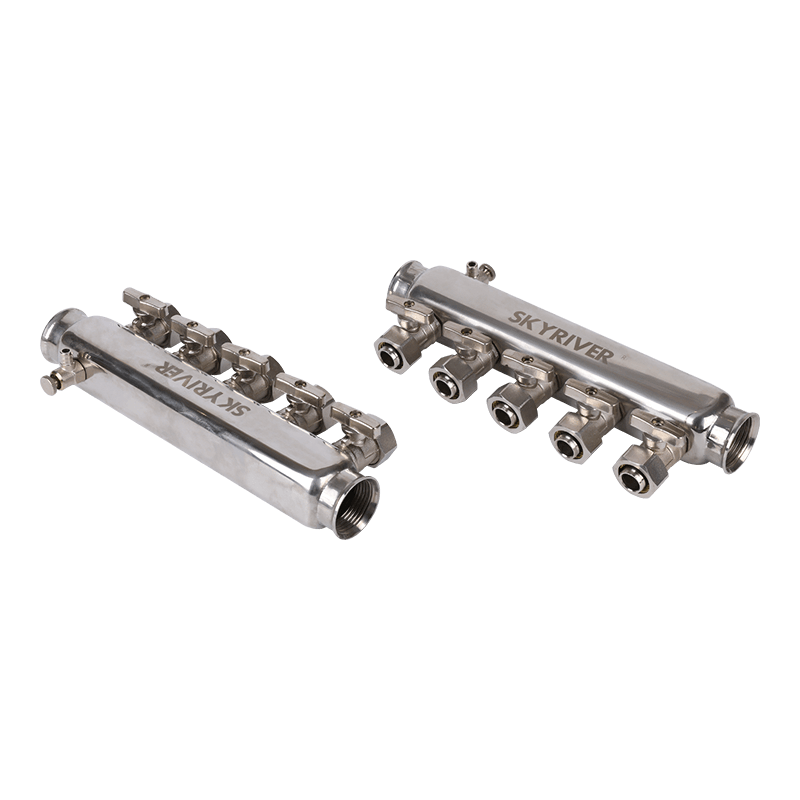

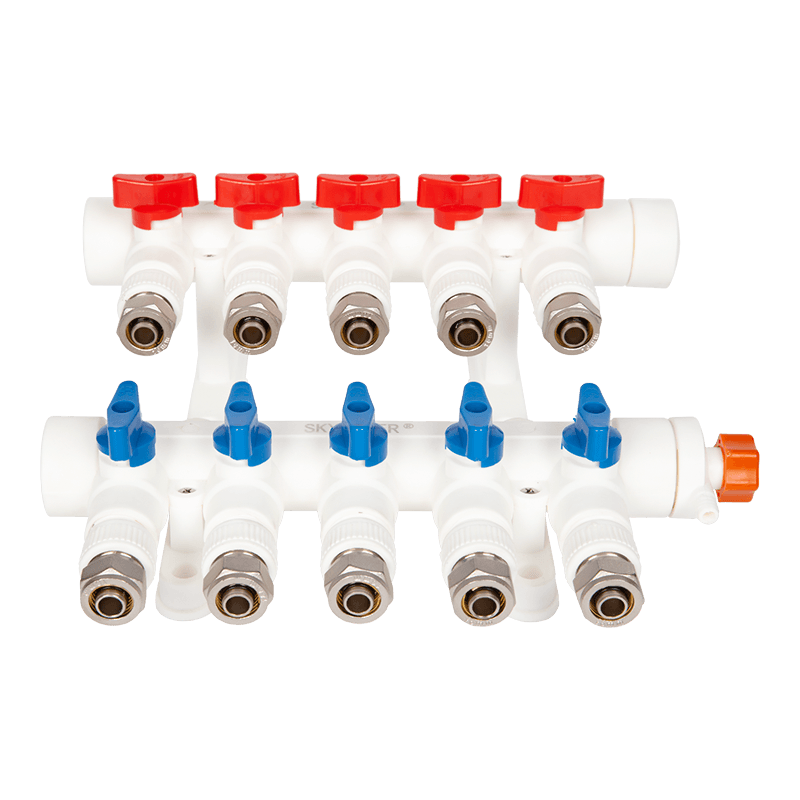

1.Manifold Body:

The main body of the manifold is typically made of durable materials like brass or stainless steel. It houses the various components and provides a structure for the entire assembly.

2.Flow Meters:

Flow meters are attached to each outlet on the manifold. They measure the flow rate of water passing through each zone or circuit. This helps in balancing the system and ensuring that each area receives the desired amount of heat.

3.Isolation Valves:

Isolation valves are installed on each outlet of the manifold and are used to control the flow of water to individual zones. These valves allow for isolating specific areas for maintenance or adjustments without affecting the rest of the system.

4.Temperature Gauges:

Temperature gauges are integrated into the manifold to monitor the temperature of the water entering and leaving the manifold. This information is valuable for system control and troubleshooting.

5.Manual Balancing Valves:

Manual balancing valves are used to adjust the flow rate to different zones manually. Balancing the system ensures that each zone receives the right amount of heated water to achieve even heating throughout the space.

6.Automatic Balancing Valves (Optional):

In some advanced systems, automatic balancing valves may be included. These valves automatically adjust the flow based on the temperature and pressure in each zone, providing continuous balancing for optimal performance.

7.Air Vents:

Air vents are positioned at the high points of the manifold to allow any trapped air to escape. This is important for maintaining efficient heat transfer and preventing air pockets that can hinder performance.

8.Drain Valves:

Drain valves are installed at the low points of the manifold to facilitate system draining for maintenance or repairs.

9.Return Manifold:

In addition to the supply manifold, there is often a return manifold. The return manifold collects the cooled water from the underfloor heating system and directs it back to the heat source for reheating.

LANGUAGE

LANGUAGE  English

English русский

русский 中文简体

中文简体