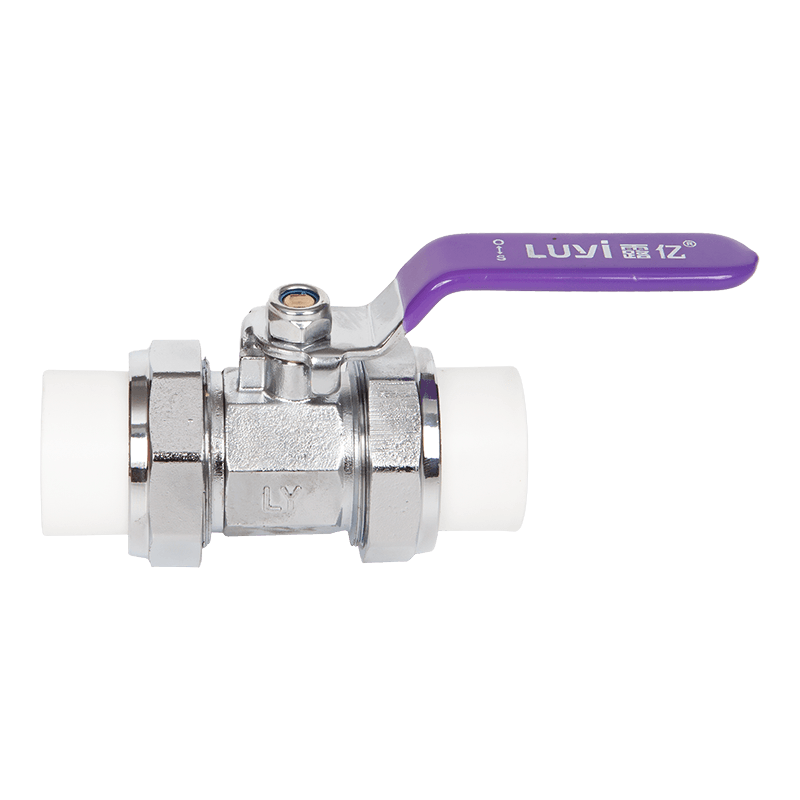

What is the basic design and construction of a brass ball valve?

A

brass ball valve is a type of quarter-turn valve that uses a perforated and pivoting ball to control the flow of liquids or gases through it.

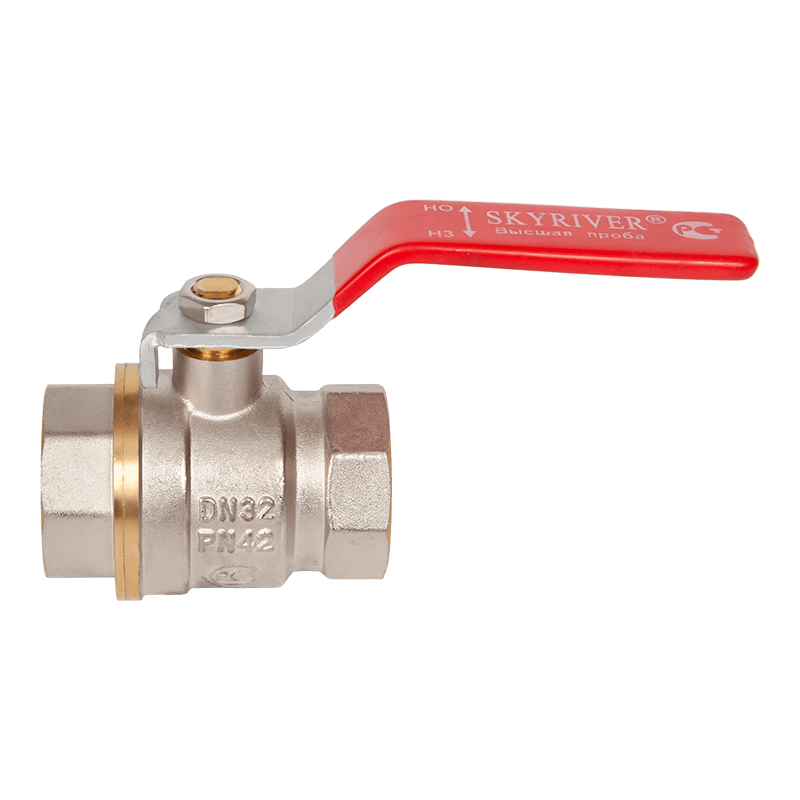

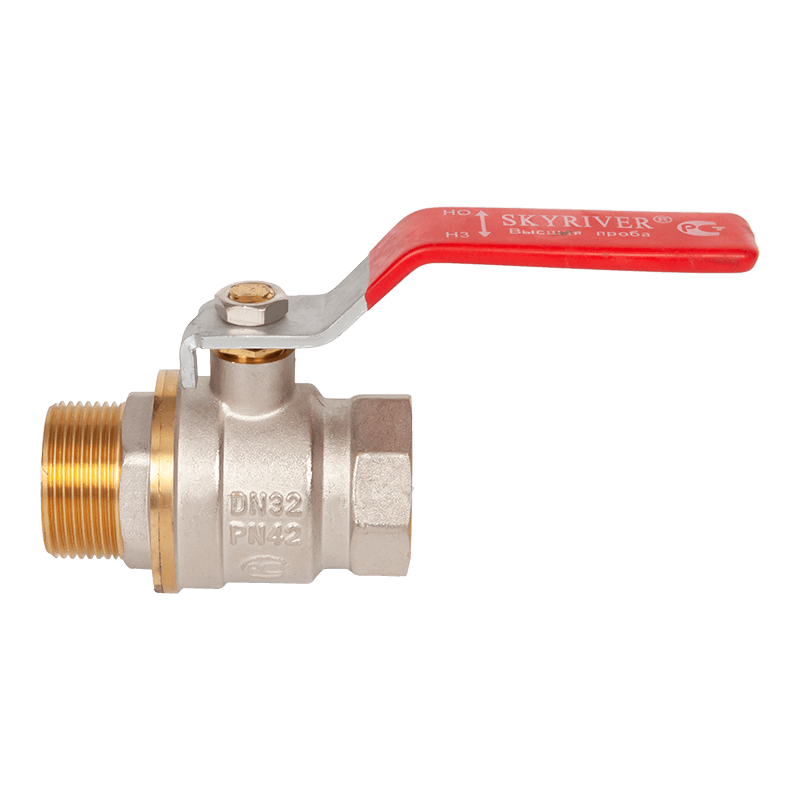

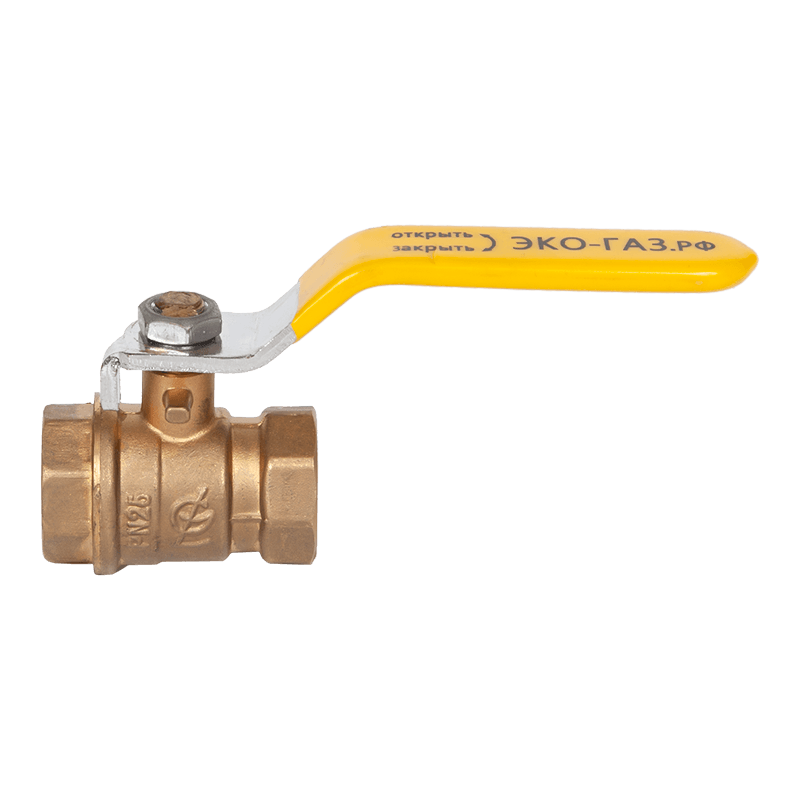

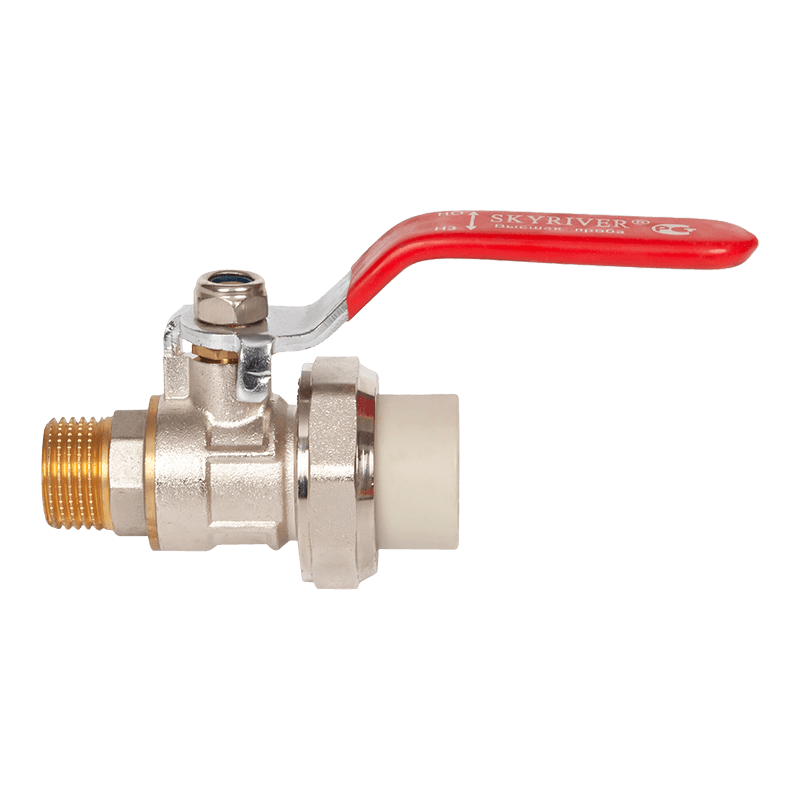

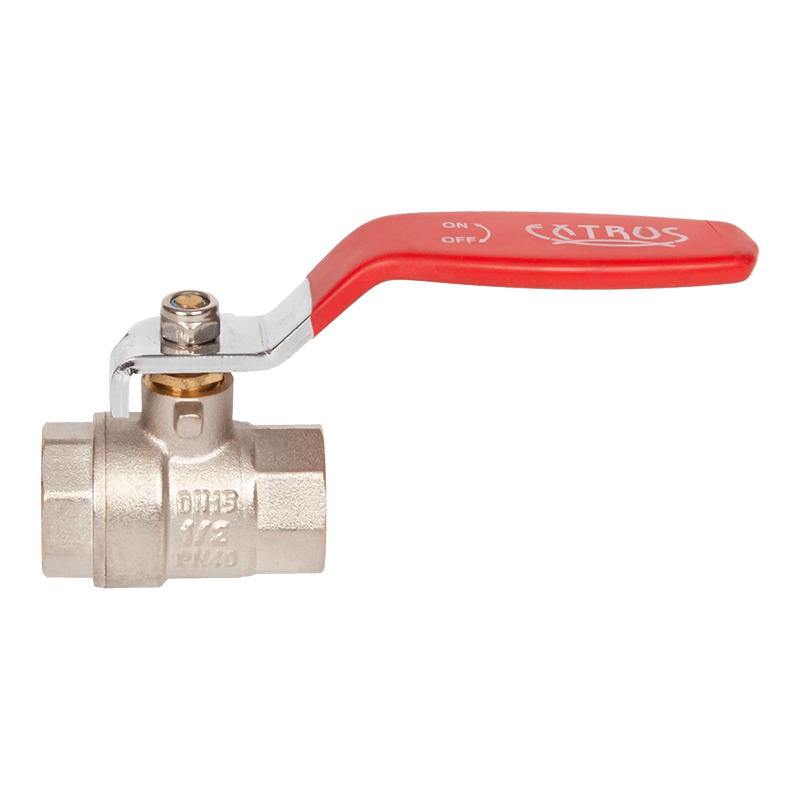

1.Body:

The body is the outer shell of the valve, typically made of brass. It provides structural support and houses the internal components of the valve. The body is threaded or otherwise connected to the plumbing system.

2.Ball:

The ball is a spherical disc inside the valve that has a hole (bore) through its center. It is usually made of brass or another durable material. The position of the ball determines whether the valve is open or closed. When the handle is turned, the ball rotates to either allow or block the flow of fluid.

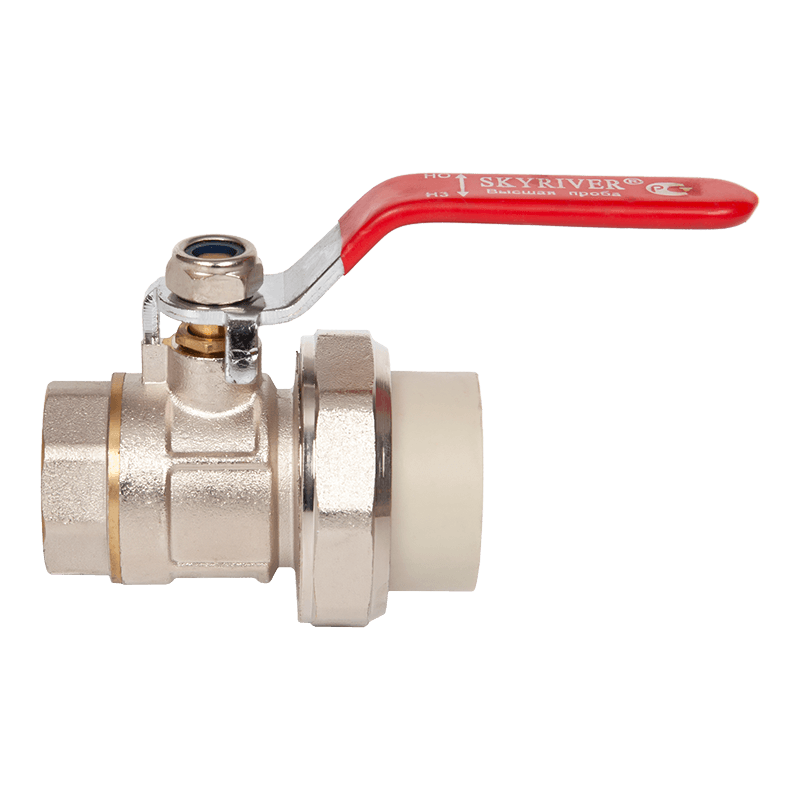

3.Stem:

The stem is a rod that connects the handle to the ball. When the handle is turned, the stem transfers the motion to the ball, causing it to rotate. The stem is often sealed to prevent leaks around the handle.

4.Seat:

The seat is a sealing surface inside the valve against which the ball makes contact when the valve is closed. It ensures a tight seal and prevents leakage when the valve is in the closed position.

5.Seals/O-Rings:

Seals or O-rings are used to create a watertight seal between the moving parts of the valve, such as the ball and the stem. These are often made of materials like rubber or Teflon to prevent leaks.

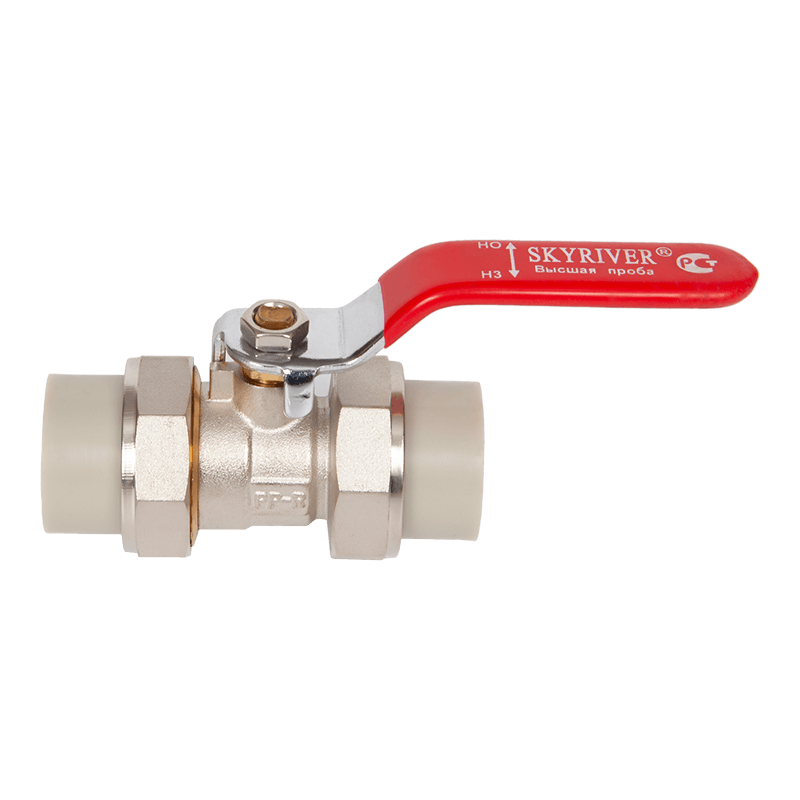

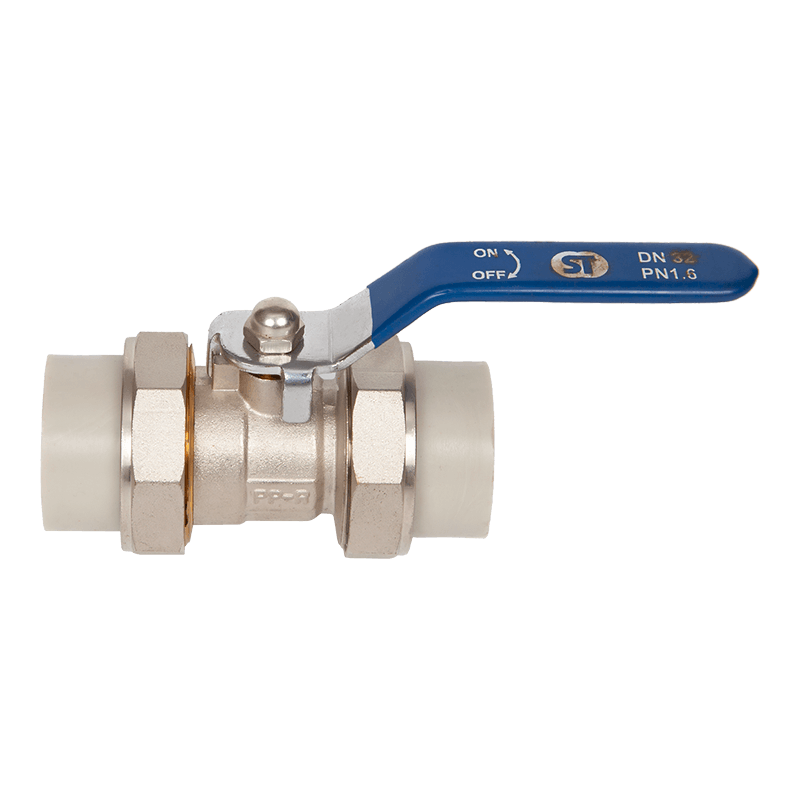

6.Handle or Lever:

The handle is the external control mechanism that the user operates to turn the valve on or off. It is typically attached to the stem and is easily rotated by hand. The position of the handle indicates whether the valve is open or closed.

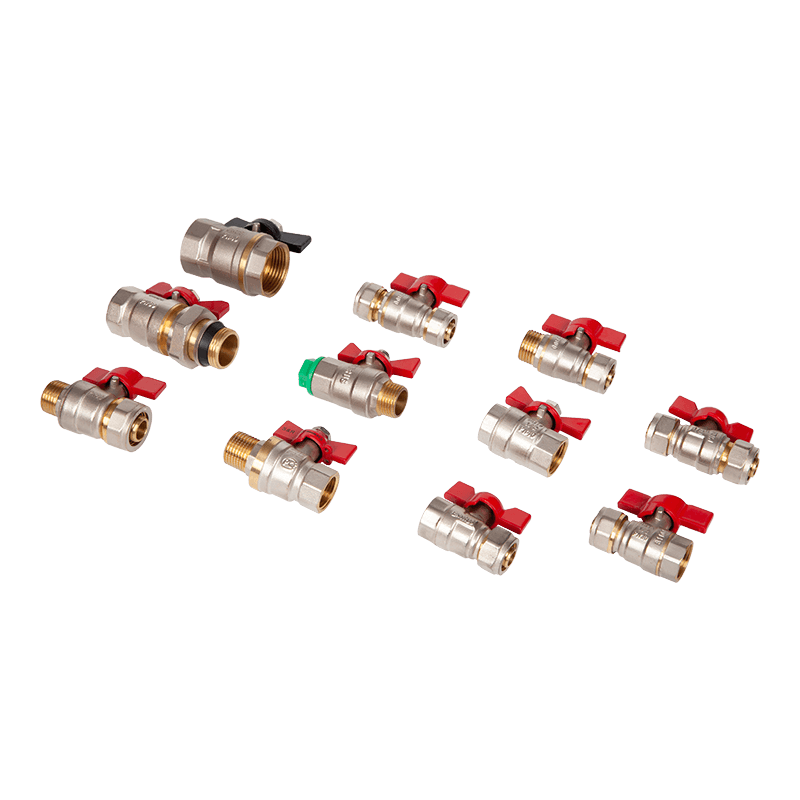

7.End Connections:

The valve has inlet and outlet ports where pipes can be connected. The end connections can be threaded, soldered, or feature other types of connections depending on the application.

8.Locking Mechanism (Optional):

Some ball valves come with a locking mechanism to prevent unauthorized or accidental operation. This is particularly useful in industrial settings or where the valve controls critical systems.

How does the ball valve mechanism work?

A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of fluid through it. The basic mechanism of a ball valve involves the rotation of a spherical ball with a hole or port through it to regulate the flow.

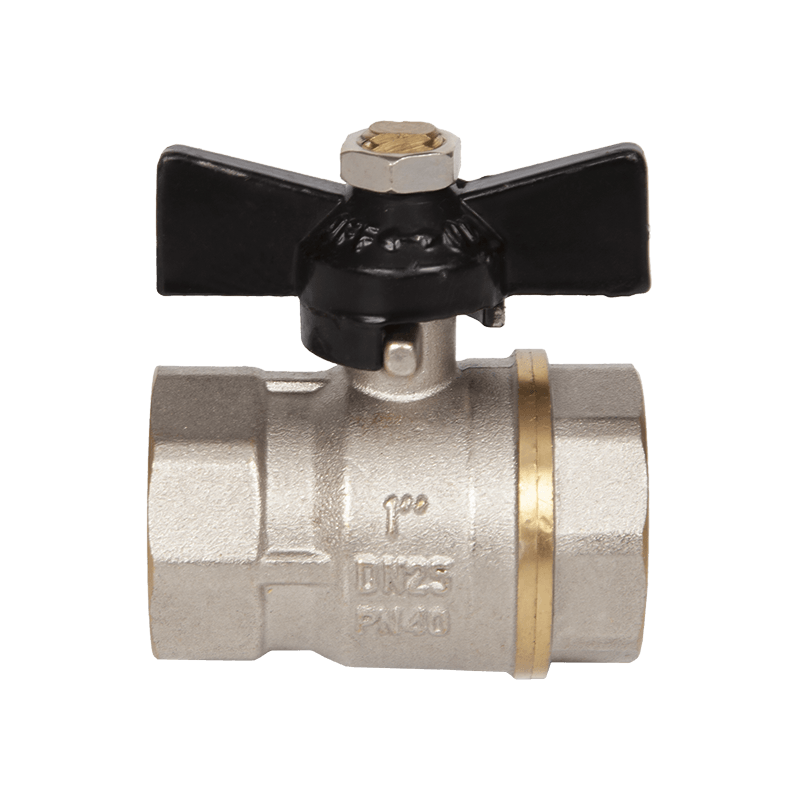

1.Valve Construction:

A typical ball valve consists of a hollow, spherical ball made of metal (such as brass or stainless steel) or other materials with excellent corrosion resistance.

The ball has a hole or port drilled through its center, creating a passage for fluid to flow when the valve is open.

2.Valve Body:

The ball is housed within a valve body, which is a chamber with inlet and outlet ports for the fluid. The valve body is usually made of metal or other durable materials.

The inlet and outlet ports are aligned with the hole in the ball when the valve is in the open position.

3.Handle or Lever:

The valve has an external handle or lever that is attached to the top of the ball.

Rotating the handle or lever by 90 degrees (a quarter turn) turns the ball inside the valve body, either aligning or misaligning the hole with the inlet and outlet ports.

4.Open Position:

When the handle or lever is turned, aligning the hole in the ball with the inlet and outlet ports, the valve is in the open position.

In this state, fluid can flow through the valve with minimal resistance, as the passage is fully open.

5.Closed Position:

When the handle or lever is turned to misalign the hole with the ports, the valve is in the closed position.

In this closed state, the solid part of the ball blocks the passage, preventing the flow of fluid through the valve.

6.Sealing Mechanism:

Many

ball valves incorporate a sealing mechanism, such as an O-ring, to ensure a tight seal when the valve is closed. The seal helps prevent leakage around the ball.

LANGUAGE

LANGUAGE  English

English русский

русский 中文简体

中文简体